1. Introduction to Copper Tube Busbars

Definition: A copper tube busbar is an electrical conductor made from pure copper, shaped into a circular tube. Due to their exceptional conductivity and durability, they are widely used in industrial electrical systems and electronic devices.

Comparison: Compared to other types of conductors like flat copper bars and aluminum bars, copper tube busbars offer several advantages:

- Conductivity: Copper has higher conductivity than aluminum, reducing energy losses during transmission.

- Heat resistance: Copper tube busbars have better heat resistance, making them suitable for high-temperature environments.

- Mechanical strength: Copper tube busbars have high mechanical strength, capable of withstanding strong mechanical impacts.

- Flexibility: The circular shape makes copper tube busbars easy to bend and install in confined spaces. Applications:

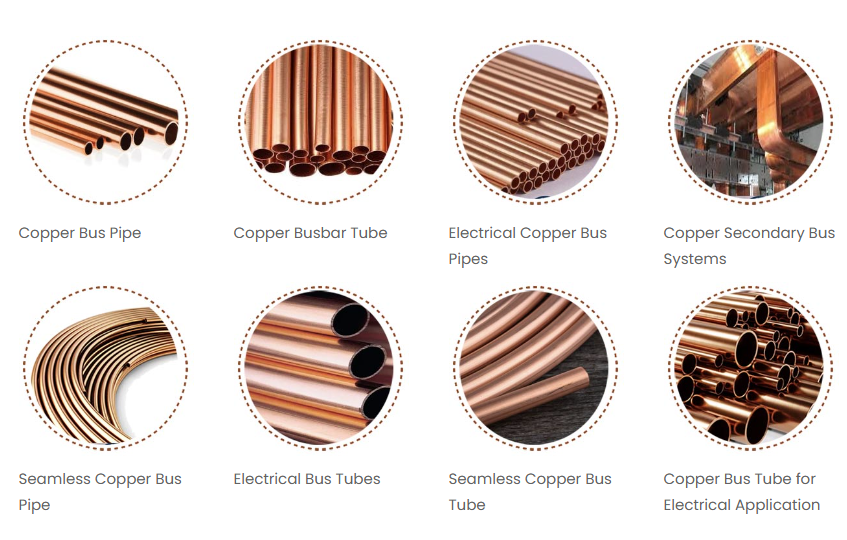

- Industrial electrical systems: Copper tube busbars are used as busbars in distribution panels, electrical substations, manufacturing plants, etc.

- Electronic devices: Copper tube busbars are used in high-power electronic devices such as inverters, UPS, etc.

- Other industries: Oil and gas, chemicals, renewable energy, etc.

2. Structure and Operating Principle

Structure:

- Material: High-purity pure copper.

- Shape: Circular tube with various sizes depending on the application.

- Joints: Joints are usually made by welding or pressing.

- Operating principle:

- Current conduction: The current flows along the inner surface of the copper tube.

- Current distribution: The copper tube busbar distributes the current evenly to the consuming devices.

- Load bearing: Thanks to its large cross-sectional area, the copper tube busbar can withstand high currents and temperatures without damage.

3. Manufacturing Process

Stages:

- Material selection: Selecting high-purity pure copper.

- Tube processing: Copper tubes are produced by drawing or extrusion.

- Welding joints: Tube sections are welded together to form a copper tube busbar of the desired length.

- Quality inspection: Checking technical parameters such as diameter, thickness, and surface smoothness.

- Quality standards: Copper tube busbars must meet international and industry standards for conductivity, mechanical strength, heat resistance, etc

4. Applications of Copper Tubular Busbars in Practice

Specific examples:

- Electrical distribution systems: Copper tubular busbars are used as busbars in electrical distribution panels to distribute power to consuming devices in factories and buildings.

- Substations: Copper tubular busbars are used to connect equipment in substations, ensuring efficient energy transmission.

- Electrical equipment: Copper tubular busbars are used as conductors in inverters and UPS systems to supply power to electronic devices.

5. Selection and Use of Copper Tubular Busbars

Factors to consider:

- Rated current: Select a busbar with a cross-sectional area suitable for the system’s rated current.

- Rated voltage: Ensure the busbar can withstand the system’s operating voltage.

- Operating temperature: Choose a busbar with good heat resistance in the working environment.

- Operating environment: Determine the working environment to select the appropriate type of busbar (indoor, outdoor, harsh environments).

Safety standards:

- Installation: Adhere to installation regulations to ensure electrical safety.

- Maintenance: Perform regular maintenance to extend the busbar’s lifespan.

- Electrical safety: Always follow electrical safety rules when working with copper tubular busbars.

6. Advantages, Disadvantages, and Comparison

Advantages:

- High electrical conductivity

- Excellent heat resistance

- High mechanical strength

- Flexibility

Disadvantages:

- Higher cost compared to other types of conductors.

- More difficult to process than some other types of bars.

7. Development Trends and Future Prospects

New technology: The trend is to develop copper tubular busbars with higher purity and better heat resistance.

Applications: Copper tubular busbars will be more widely applied in new industries such as renewable energy and electric vehicles.