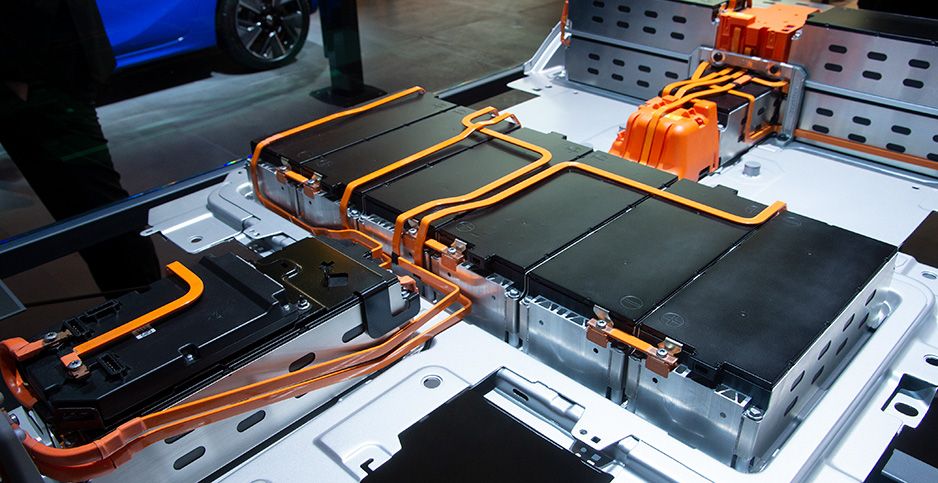

Shogo Vietnam.,JSC established in 2018, locates in Pho Noi A Industrial Park, An Lac Hamlet, Nhu Quynh Commun, Hung Yen Province, Viet Nam. It covers an area of 6.200 square meters and it has about 100 staffs. It is an hi-tech enterprise with research & development, production and sale, We have professional R&D, production teams with experienced management. We keep on technology innovation to fullfill customers’ specific requirement. With our high quailt product and considerate pre-sale & after sale service, we have gained positive feedback from our valuable customers from domestic and oversea. Our products have gained ISO 9001:2015, IATF16949:2016, ISO 14001:2015, ISO/IEC 17025:2017 certificates.Our products’ category includes flexible copper/aluminium busbar used in new energy line, copper/aluminium foil busbar, fabricated copper busbar, braid wire, copper earth wire/terminal, copper/alu. Busbar, copper/aluminium conductor as a accessories used in switch and other equipments.Our products are widely used in battery in new energy automobile car factory, energy saving communication power supply cabinet factory, electricity and electric power engigeering, high-low voltage power distribution equipment, welding equipment company, electronic and electric appliance plants.Our process equipments for flexible busbar are imported from Germany, and automatic process equipments are famous brand in domestic, such as automatic welding, strong power and special welding, automatic induction welding and its acceessories, also with series specialty inspection equipments.