1. What Is a Busbar?

A busbar is a conductor used to distribute electric power, commonly found in electrical systems. Although both EV busbars and industrial busbars serve the same purpose—transmitting electricity—they differ significantly in design, materials, and technical specifications.

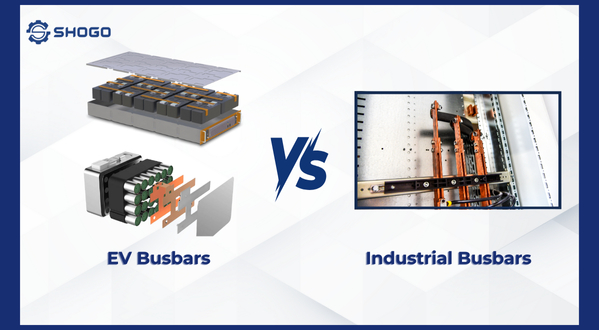

2. What Is an EV Busbar?

An EV busbar is a specialized conductor designed for electric vehicle systems, particularly battery packs, controllers, inverters, motors, and charging circuits.

Key features of EV busbars:

- Material: Typically made from copper or aluminum with tin plating, often insulated with polyimide or epoxy.

- Design: Thin, lightweight, and compact, often flexible to fit tight spaces.

- Insulation: Always coated with an insulating layer to prevent short circuits and leakage in compact environments.

- Vibration and temperature resistance: High—suitable for dynamic, mobile conditions in vehicles.

- Current capacity: Low to medium (tens to hundreds of amps), but must allow fast response and minimal voltage drop.

3. What Is an Industrial Busbar?

Industrial busbars are conductors used in factories, power panels, substations, and electrical infrastructure.

Key features of industrial busbars:

- Material: Mostly bare copper or aluminum, with optional insulation.

- Design: Rigid, thick conductors built to handle very high current loads (up to several thousand amps).

- Size and weight: Bulkier and heavier; flexibility not a concern.

- Insulation: Optional; depends on enclosure design and installation spacing.

- Purpose: Continuous, stable, high-capacity power transmission in fixed installations.

4. Comparison Table: EV Busbar vs. Industrial Busbar

| Criteria | EV Busbar | Industrial Busbar |

|---|---|---|

| Material | Copper/aluminum with tin plating + insulation | Bare copper or aluminum (optional insulation) |

| Design | Slim, light, flexible | Thick, rigid, built for high current |

| Insulation | Always insulated | May be bare or insulated depending on setup |

| Current rating | Tens to hundreds of amps | Hundreds to thousands of amps |

| Vibration/Heat Resistance | High (mobile environment) | Lower (static environment) |

| Application | Battery packs, EV inverters, motors | Distribution boards, substations, factories |

5. Choosing the Right Busbar for Your Application

For EV Applications:

- Choose lightweight, compact, insulated designs.

- Flexible structures for tight, complex installation spaces.

- Must meet standards like ISO 16750, LV 214, or OEM EV requirements.

For Industrial Applications:

- Focus on high ampacity and robust thermal performance.

- Thicker conductors, with or without insulation depending on environment.

- Comply with IEC 61439, IEC 60865, or national technical standards.

6. Conclusion

Although they share the same name, EV busbars and industrial busbars serve very different purposes. Using the wrong type could lead to overheating, short circuits, or system failure.

- EV busbars: lightweight, insulated, for dynamic environments.

- Industrial busbars: large, durable, optimized for heavy-duty, stable systems.

Need Help Choosing the Right Busbar?

We supply custom busbars for both EV and industrial systems, built to exact technical specifications and safety standards. Contact our engineering team today for a quote or expert consultation tailored to your needs.