1. Factors affecting the performance of Busbar

Busbar plays a key role in the power system, especially in solar power systems, responsible for transmitting electricity from supply sources (such as solar cells, generators) to loads. (like inverter, transformer). The performance of the busbar directly affects the efficiency of power transmission, contributing to determining the energy efficiency of the entire system. This article will give you a more detailed view of the factors that affect busbar performance, and propose optimal solutions to improve busbar performance in real application.

1.1. Material:

- Conductive material:

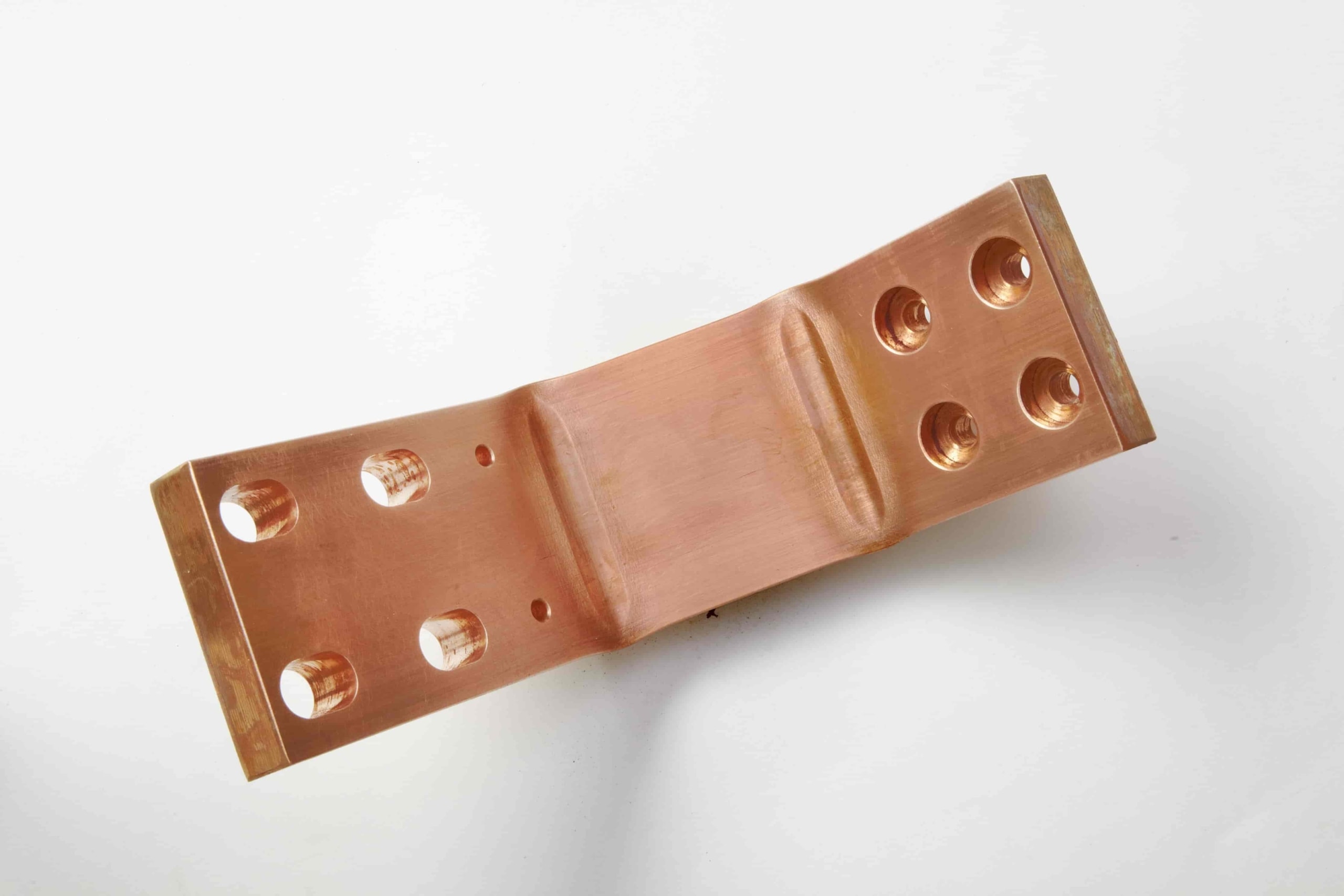

Copper: The most popular choice due to its high conductivity (about 59.6 S/m at 20°C), allowing large current transmission with low loss. However, the cost of copper is higher than that of aluminum.

Aluminum: Reasonable alternative material with cheaper price and lighter weight (about 37.7 S/m at 20°C), suitable for applications that need to save costs and reduce mechanical loads.

- Coating:

Tin: Enhances electrical conductivity, prevents corrosion and protects the busbar from environmental impacts.

Silver: Improves electrical conductivity performance, especially useful in applications with high current requirements.

1.2. Design:

Size: Busbar size needs to be selected in accordance with the current to be transmitted. Using a busbar that is too small can lead to power loss due to increased temperature, while a busbar that is too large will increase initial investment costs.

Shape: Busbar can have many different shapes such as rectangle, circle or bar.

- Rectangular: Most popular due to ease of production and installation.

- Round shape: Better heat dissipation efficiency, reducing the risk of overheating.

- Bar shape: Saves installation space, suitable for applications with limited area.

Number of busbars: Busbar can have one or more parallel busbars. The higher the number of conductor bars, the higher the electrical conductivity but also increases the cost.

1.3. Environmental conditions:

- Temperature: High ambient temperature reduces the conductivity of the busbar, leading to power loss. Therefore, it is necessary to install the busbar in a well-ventilated area, away from direct sunlight and other heat sources.

- Humidity: High humidity facilitates galvanic corrosion of the busbar, reducing performance and lifespan. It is necessary to use a busbar with anti-corrosion coating or install the busbar in a low humidity environment.

- Contaminants: Dirt, salt, chemicals,… adhering to the busbar can reduce conductivity and increase the risk of electric discharge. It is necessary to clean the busbar periodically and protect the busbar from pollutants.

1.4. How to install:

- Installed in the correct location: Busbar needs to be installed in the correct location according to the design diagram, ensuring a safe distance between the busbars and other parts in the electrical system.

- Firmly fixed: Use suitable brackets and accessories to firmly fix the busbar, avoiding vibration during operation.

- Firm connection: Make connections between busbars according to correct techniques, ensuring good contact and avoiding contact resistance.

- Protection: Use covers or insulating paint to protect the busbar from mechanical, chemical and environmental impacts.

1.5. Management and operation:

- Periodic inspection: Periodically check the busbar to detect and fix damages such as cracks, corrosion, loose joints,…

- Cleaning: Clean the busbar regularly to remove dirt, salt, and chemical adhesion, ensuring conductivity and performance.

2. Solution to optimize Busbar performance

To improve the performance of the busbar and ensure the electrical system operates safely, efficiently, and saves energy, the following solutions need to be implemented:

2.1. Choose suitable materials:

- Determine the exact current to be transmitted: Based on the technical specifications of the electrical system, select a busbar material with appropriate electrical conductivity.

- Pay attention to environmental factors: If the operating environment has humidity, high temperature or pollutants, priority should be given to using a busbar with anti-corrosion coating or choosing a conductive material that is resistant to Good resistance to harsh environmental conditions.

- Choose a reputable supplier: Ensure the quality of busbar materials and coatings meet technical standards, safety for users and electrical systems.

2.2. Optimal design:

- Calculate accurate busbar size: Use specialized software or electrical calculation formulas to determine the busbar size appropriate to the current to be transmitted, ensuring effective conduction and minimizing power loss. .

- Choose the appropriate busbar shape: Depending on the installation conditions and requirements for heat dissipation efficiency, choose the appropriate busbar shape such as rectangular, circular or bar-shaped.

- Use the optimal number of conductor bars: Find a solution that balances conductivity efficiency and cost by choosing the appropriate number of conductor bars for the current to be transmitted.

2.3. Correct installation and operation:

- Follow the installation instructions: Install the busbar according to the manufacturer’s instructions, ensuring a safe distance, a secure connection, and a secure busbar fixation.

- Protect the busbar from environmental impacts: Use covers or insulating paint to protect the busbar from dirt, water, chemicals and other pollutants.

- Perform periodic inspection and maintenance: Inspect the busbar periodically to detect damage, clean the busbar regularly and perform maintenance measures as recommended by the manufacturer.

2.4. Apply advanced technology solutions:

- Use the busbar monitoring system: Monitor temperature, humidity, voltage, current at important points on the busbar, detect early signs of abnormalities and take timely measures.

- Apply advanced heat dissipation techniques: Use heat dissipation materials, fans or liquid cooling systems to enhance the busbar’s heat dissipation ability, especially in high temperature environments.

By applying the above solutions, it is possible to optimize busbar performance, improve energy efficiency, ensure safety and extend the life of the electrical system.

3. Conclusion:

Busbar plays an important role in the electrical system, directly affecting the performance and reliability of the system. Choosing the right materials, optimal design, correct technical installation and operation, combined with the application of advanced technology solutions will help optimize the performance of the busbar, bringing many benefits. Benefits for the electrical system and users.