1. Introduction

Busbars play a crucial role in factory electrical systems by efficiently, safely, and reliably transmitting electrical energy. Selecting the appropriate busbar not only optimizes system performance but also minimizes operational risks and costs. In this article, we will explore the key criteria for choosing the right busbar for your factory’s electrical system.

2. What is a Busbar?

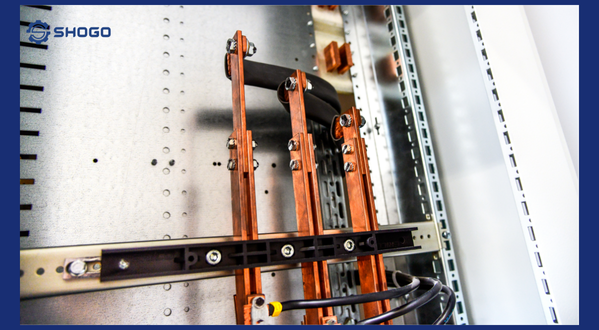

A busbar is an electrical conductor that transmits large amounts of electricity within an electrical system. Typically made of copper or aluminum, busbars come in various shapes, such as flat bars, box bars, or flexible bars. They are widely used in electrical cabinets, substations, and power distribution systems.

3. Criteria for Choosing the Right Busbar

3.1. Determine Power Requirements

- Assess the total power consumption of your system to select a busbar with appropriate load capacity.

- Ensure optimal energy transmission without overloading the busbar.

- Consider future power demand growth to prevent overloading after system expansion.

3.2. Choose the Busbar Material

- Copper Busbar: High electrical conductivity, excellent heat resistance, and long lifespan. Ideal for systems requiring high performance.

- Aluminum Busbar: Lightweight, cost-effective, and easy to install. Suitable for systems focused on cost optimization with moderate power demands.

3.3. Determine Busbar Size and Cross-Section

- Select the appropriate cross-section based on the current capacity and power requirements.

- Ensure the cross-section is large enough to prevent overheating and reduce energy loss.

- Use standard formulas to calculate the cross-section considering the rated current and allowable temperature rise.

3.4. Busbar Shape and Structure

- Flat Busbar: Ideal for electrical cabinets and power distribution boards.

- Box Busbar: Provides better protection, suitable for high-current systems.

- Flexible Busbar: Offers flexibility to reduce vibrations, ideal for systems with movement or thermal expansion.

3.5. Heat Resistance and Corrosion Protection

- Choose busbars with anti-oxidation or tin-plated coatings to prevent corrosion.

- Ensure high heat resistance to maintain optimal power transmission.

- Select busbars certified to meet international electrical safety standards.

3.6. Flexibility and Expandability

- Consider expandability and ease of upgrade when selecting busbars.

- Choose busbars designed for easy installation, maintenance, and replacement.

- Ensure flexibility in connecting to other electrical components.

4. Applications of Busbars in Factory Electrical Systems

- Main Power Distribution Systems: Provide stable and safe electrical power for the entire factory.

- Electrical Cabinets and Distribution Boards: Distribute electricity to various sections and equipment.

- Industrial Machinery Systems: Deliver electricity directly to production equipment.

- Renewable Energy Systems: Optimize energy transmission in solar and wind power stations.

- Substations: Connect transformers and circuit breakers for stable operation.

5. Installation Considerations for Busbars

- Ensure all busbar connections are securely tightened and properly contacted.

- Use appropriate insulation or protective covers.

- Perform regular inspections to detect early signs of overheating or oxidation.

- Follow electrical safety standards during installation.

6. Conclusion

Choosing the right busbar for your factory electrical system is a key factor in ensuring operational efficiency and electrical safety. By considering factors such as power capacity, material, size, shape, and heat resistance, you can make the best decision for your system. Investing in the right busbar not only optimizes production operations but also reduces maintenance costs and technical failures.

Conduct thorough research and consult with experts to make an informed decision for your factory’s electrical system.