In electric motorcycle battery packs, busbars serve a critical role in connecting individual cells and transferring current from the battery module to the controller and motor. Choosing the wrong type of busbar can lead to localized overheating, increased contact resistance, or even safety hazards like short circuits or fires. Below are the most important technical and practical criteria to evaluate when selecting busbars for EV batteries.

1. Core Material: Copper or Aluminum?

| Criteria | Copper Busbar | Aluminum Busbar |

|---|---|---|

| Electrical conductivity | Very high (30–35% higher) | Lower, but acceptable |

| Weight | Heavier | Much lighter |

| Weldability | Easy to work with, compatible with ultrasonic welding | Harder to weld, requires special equipment |

| Cost | More expensive | More affordable |

| Best use case | High-performance systems | Cost-effective or lightweight systems |

Suggestion: For mid- to high-end electric motorcycles, copper busbars are recommended due to their superior conductivity and long-term stability.

2. Oxidation Protection: Is Tin Plating Necessary?

A tin-plated surface (Sn coating) is crucial if the vehicle operates in environments with fluctuating temperature and humidity.

-

Prevents oxidation and corrosion at contact points.

-

Reduces contact resistance between the busbar and battery cells.

-

Enhances weldability—especially with ultrasonic or resistance welding.

Note: Select a tin layer thickness of at least 5 µm, with uniform and firmly bonded coating.

3. Busbar Thickness and Cross-Section

-

Typical thickness: 0.5 to 2.0 mm.

-

Width and shape depend on the battery module design.

-

A larger cross-sectional area improves current-carrying capacity and reduces heat buildup.

-

Ensure the busbar can handle peak current, especially during acceleration or uphill rides (e.g., at least 80–100A for a 72V – 40Ah battery).

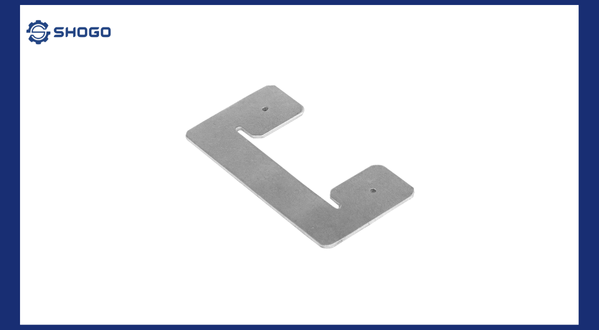

4. Flexibility in Custom Fabrication

A good busbar isn’t just about material—it must also be precision-machined:

-

Should be cut, drilled, stamped, or bent as required.

-

Must match the battery layout (e.g., 10s, 13s, 17s modules).

-

Requires tight dimensional tolerance for reliable welding.

-

Ideally, the supplier provides CAD drawings or technical files for bulk orders.

5. Source and Technical Certifications

Don’t overlook quality assurance:

-

Request documentation of material origin: CO (Certificate of Origin), CQ (Certificate of Quality).

-

Inspect coating uniformity using thickness gauges or profile testing.

-

Verify corrosion resistance through salt spray testing (ASTM B117) for 48–72 hours.

Summary: 5 Essential Factors When Selecting Busbars for Electric Motorcycles

| Factor | Target Objective |

|---|---|

| Core material | Ensure high conductivity and stable performance |

| Oxidation protection layer | Prevent corrosion, extend connection life |

| Suitable cross-section | Handle high current, minimize heat generation |

| Customizable design | Match the specific battery module layout |

| Verified quality control | Minimize technical risks, improve long-term reliability |

If you’re a manufacturer or R&D engineer, consider working with a supplier who has experience in lithium battery systems. A good supplier can not only provide materials but also assist in optimizing the overall layout and busbar integration. I can also help you define a more detailed technical specification document if needed.