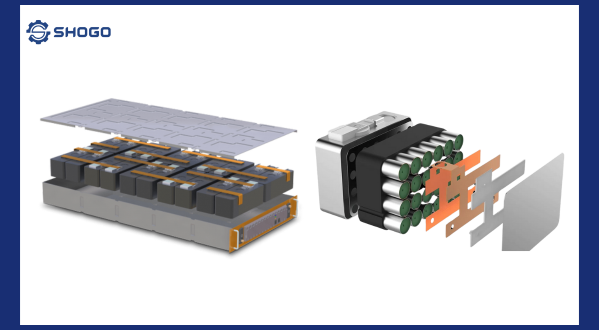

In the electric vehicle (EV) industry, the battery system is the heart of performance, durability, and safety. One of the lesser-known but critically important components influencing a battery pack’s reliability is the busbar—the metal conductor that connects individual battery cells. This article explores how busbars affect the stability and safety of EV batteries, especially in high-power applications.

1. What is a Busbar in an EV Battery System?

A busbar is a metallic strip (usually made of copper or aluminum) used to connect individual battery cells or modules into a unified electrical system. It is responsible for carrying high current, ensuring even power distribution, and minimizing energy loss due to electrical resistance.

2. How Busbars Affect Battery Pack Stability

| 🔧 Stability Factor | 🔍 Busbar Contribution |

|---|---|

| ⚡ Stable current transmission | High-quality busbars ensure smooth current flow with minimal resistance or losses. |

| 🌡️ Thermal management | Well-designed busbars dissipate heat efficiently, preventing cell overheating. |

| 🧲 Reduced electromagnetic interference (EMI) | Optimized layout minimizes EMI, improving overall system accuracy. |

| 🔋 Cell voltage balancing | Uniform busbar dimensions and materials help distribute voltage evenly between cells. |

3. How Busbars Impact Battery Pack Safety

| ☂️ Safety Factor | 🛠️ Busbar Design & Material Considerations |

|---|---|

| 🔥 Fire and thermal runaway risks | Thin or poorly cooled busbars can overheat, leading to short circuits or fire. |

| 💥 Short-circuit and arcing risks | Poor welding or insulation may cause internal shorts with catastrophic effects. |

| 🔌 Electric leakage | Inadequate insulation on busbars can lead to leakage—especially in humid environments. |

| ⚙️ Mechanical damage | Weak or poorly mounted busbars can crack or detach under vibration, causing failures. |

4. Emerging Trends in EV Busbar Design

| Trend | Description |

|---|---|

| Flexible Busbars | Adapt to vibration and thermal expansion, improving mechanical lifespan. |

| Laser-Welded Busbars | Provide precise, low-heat, and durable electrical joints. |

| Composite Busbars | Combine copper, aluminum, and insulation layers for better performance and safety. |

5. Conclusion: Busbars – The “Silent Arteries” of EV Battery Reliability

While they may not get the spotlight like lithium-ion cells or BMS (Battery Management System), busbars are central to energy transmission and system protection. A well-engineered busbar not only improves efficiency but also reduces safety risks and extends battery life.

Therefore, automotive manufacturers must invest in busbar materials, welding techniques, and structural designs as part of their strategy to enhance vehicle reliability and safety.