1. Introduction

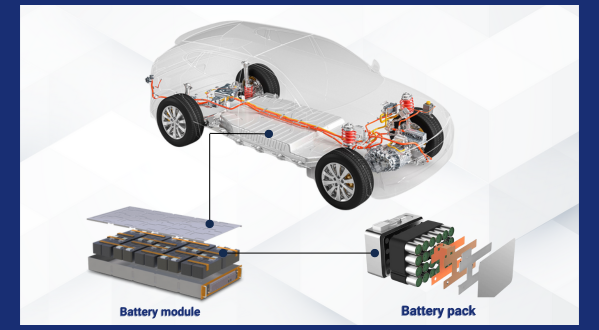

As we know, busbars play an important role in connecting the battery cells in electric vehicle batteries. To better understand this role, we need to delve into the structure of a typical electric vehicle battery pack and analyze how the busbar works.

2. Structure of an electric vehicle battery pack and the role of the busbar

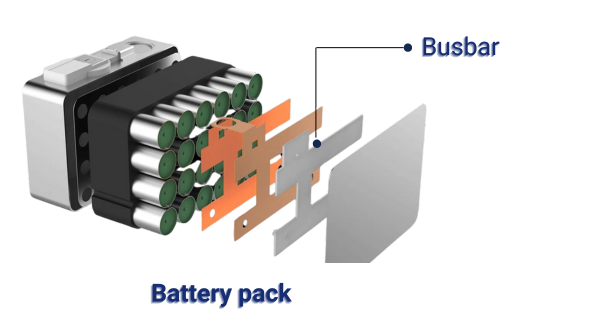

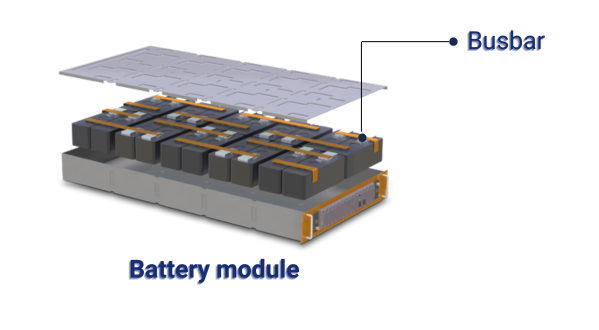

An electric vehicle battery pack consists of hundreds or thousands of battery cells connected together to form a large power source. These battery cells are arranged into modules, and the modules are connected together to form a battery pack.

- At the battery cell level: The busbar creates short and efficient conduction paths between the positive and negative poles of the battery cells in the same module. This helps to minimize internal resistance, enhance conductivity and ensure voltage balance between the battery cells.

- At the module level: The busbar connects the modules together, forming a larger conductive network. This allows the current to be distributed evenly to all modules, ensuring the performance of the entire battery pack.

- At the battery pack level: The busbar connects the modules to the battery management system (BMS) and other electrical components of the vehicle, such as the electric motor, controller.

3. Advantages of using busbar in battery cell connection

- Effective conduction: Busbar is made from good conductive materials such as copper or aluminum, helping to minimize power loss due to the Joule-Lenz effect.

- High durability: Busbar is capable of withstanding large currents, high temperatures and mechanical impacts, ensuring the durability of the battery pack.

- Flexibility: Busbar can be designed in many different shapes and sizes to suit different types of batteries and battery structures.

- Safety: Busbar is designed with high safety standards, minimizing the risk of electrical short circuit and ensuring safety for users.

- Voltage balancing: Busbar helps distribute current evenly to all battery cells, helping to balance voltage and increase battery life.

- Weight reduction: Compared to traditional connection methods, busbar is often lighter in weight, helping to reduce the mass of the battery pack.

4. Factors affecting busbar performance

- Material: The material used to make the busbar (copper, aluminum) directly affects the conductivity and cost.

- Size: The size of the busbar needs to be designed to suit the rated current to avoid overheating.

- Shape: The shape of the busbar affects the contact area between the busbar and the battery cell, which in turn affects the conductivity.

- Connection method: The method of connecting the busbar to the battery cell (welding, pressing, screwing) affects the durability and reliability of the connection.

- Working environment: Harsh working environments (high temperature, high humidity) can affect the performance of the busbar.

5. Conclusion

Busbars play an important role in connecting battery cells in electric vehicle batteries. Thanks to their outstanding advantages, busbars help to enhance the performance, durability and safety of the battery pack. However, to optimize the performance of busbars, careful design and appropriate material selection are required.