1. Introduction

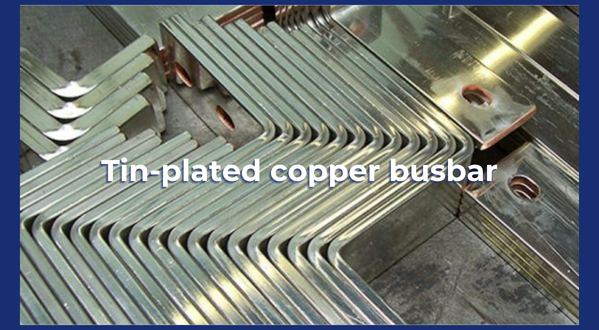

A busbar is an essential component in electrical systems, serving as a conductor to create electrical connections and distribute power. Tin plating involves coating a busbar with a thin layer of tin. This tin coating protects the busbar from oxidation and corrosion, enhancing its conductivity.

Typically made of copper or aluminum, tin-plated busbars have a tin layer varying in thickness from a few to several tens of micrometers, depending on specific requirements. They are classified based on shape (round, square, rectangular), size, and application.

2. Reasons for Using Tin-Plated Busbars

Tin offers several advantages, including excellent conductivity, corrosion resistance, high ductility, easy processing, and an aesthetically pleasing appearance. These properties make tin-plated busbars superior to unplated ones:

- Increased lifespan: The tin coating protects the busbar from environmental factors, extending its service life.

- Enhanced stability: It ensures stable electrical system operation, minimizing failures.

- Reduced risks: It lowers the risk of fires caused by poor connections.

- Improved aesthetics: Tin-plated busbars have a shiny, attractive finish.

3. Manufacturing Process

The production process involves:

- Material preparation: Selecting suitable materials (copper or aluminum) and plating chemicals.

- Busbar processing: Shaping the busbars to the desired dimensions.

- Surface cleaning: Thoroughly cleaning the busbar surface for optimal coating adhesion.

- Tin plating: Applying tin using methods like electroplating, hot-dip plating, or spray plating.

- Quality inspection: Verifying coating thickness, adhesion, conductivity, and other properties.

4. Applications

Tin-plated busbars find extensive use in:

- Electrical industry: Electrical panels, switchboards, household appliances, and industrial power systems.

- Other industries: Electronics, automotive, and aerospace.

5. Standards and Quality

Tin-plated busbars must meet quality standards, including:

- Coating thickness: Ensuring the coating meets specified thickness requirements.

- Adhesion: The coating must adhere firmly to the busbar surface.

- Conductivity: Ensuring excellent conductivity.

- Mechanical strength: Ensuring sufficient strength to withstand operational stresses.

6. Considerations for Use

- Storage: Avoid exposure to chemicals and strong impacts.

- Cleaning: Regular cleaning is essential for optimal performance.

- Repair: Damaged busbars should be repaired or replaced promptly.

7. Future Trends

- New plating technologies: Development of advanced plating techniques like vacuum plating and ion plating for improved coating quality.

- Alternative materials: Research into new alloys to replace copper and aluminum.

- New applications: Expanding the use of tin-plated busbars in smart electronic devices and renewable energy systems.

Conclusion

Tin-plated busbars are crucial components in the electrical industry. Their superior properties and wide range of applications make them a preferred choice. Ongoing advancements in materials and manufacturing processes will further enhance their performance and expand their use.