Bending busbar is aluminum busbar bended into the angels that fits the actual use of power connection. It would be Tin, nickel and silver plated.

Electrical Vehicle Powertrain Bending Aluminum Busbar

The Aluminum is cut by waterjet cutting machine or wire-electrode cutting. One end is not in equal width. The hole is fabricated in same way in once. If the width is equal, the usual dealing way is punching with mold. The second way is with less cost usually for normal equal size in high quality. The daily production speed is also higher.

The insulation material is soft PVC and covered by dipping. We also have heat shrink tube and epoxy powder coating. They have different technical data and used in different design and environment.

The aluminum is usually used in vehicles to reduce the weight of products. The current carrying ability of aluminum busbar is a little lower than copper material. So some motor company also use flexible copper foil busbar. Aluminum Flexible busbar also work well on the aspect of anti-shock ability.

1. Improve equipments properity

Copper busbar can reduce the resistance and lower consumption. Copper busbar is capable of steady current carrying capacity and voltage-sharing.

2. Easy to install, examine and maintain

Copper busbar can be installed with simple tools. Anyone can use it with bolts, nut and screwdriver. The workers examine the property with tester.

3. Reduce cost

Copper busbar increase the serve-life of machines and equipments. Good quality T2 copper material can lower the temperature raise and loss of equipments parts.

We are specialized in copper and aluminium busbar that is applied in battery, energy storage system & electric vehicles.

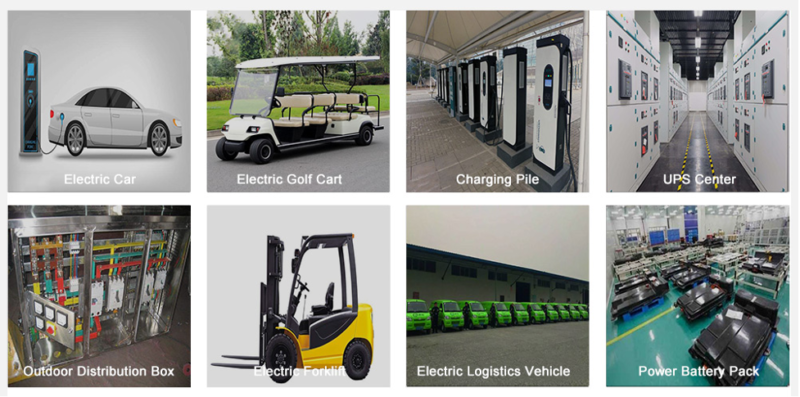

Electric vehicles like hybrid battery car, electric golf car, electric logistic vehicle, electric bus, high-speed rail, electric forklift etc.

We supply directly to many battery pack companies and energy storage companies like solar energy household storage projects in UK, Americal, Australia etc. offering solutions for their battery connecting. They use both flexible and solid copper busbar to meet different design and application requirments.

Recommend

ALUMINUM BUSBAR

ALUMINUM BUSBAR